Screw Piling Frequently Asked Questions...

What are typical projects that Screw Piles are used on ? ………………………. ![]()

What are Screw Piles and how do they work ? ………………………………………… ![]()

What are the advantages of using Screw Piles ? …………………………………….. ![]()

What are typical load capacities,

lengths in-ground, type of connection ? ……………………………………………………. ![]()

What does the Screw Pile Design involve ? ……………………………………………… ![]()

What are typical projects that Screw Piles are used on ?

What are Screw Piles and how do they work ?

What are the advantages of using Screw Piles ?

What are typical load capacities,lengths in-ground, type of connection ?

What does the Screw Pile Design involve?

How are Screw Piles installed?

What does the Screw Pile Construction Program involve ?

(Lead Time – Site Preparation – Logistics –Site Crew-ITP’s-WHSE Documentation)

What are typical projects Screw Piles are used on?

Residential

- Houses

- Town Houses

- Apartments

- Granny Flats

- Swimming Pools

- Garages

- Decks

- Retaining Walls

Commercial

- Aged Care Facilities

- Mixed Commercial

- Hotels / Motels

- Supermarkets

- Storage Facilities

- Retirement Villages

- Service Stations

- Warehouses

Infrastructure

- Aquatic Centres

- Ambulance Depo

- Community Centres

- Medical Facilities

- Schools

- Sporting Facilities

- Pavilions / Walkways

- Research Facilities

….. and more

Industrial and Civil

- Gantry Foundations

- Tanks

- Culverts

- Floodlighting

- Signage

- Carparks

- Industrial Units

- Warehousing

What are Screw Piles and how do they work?

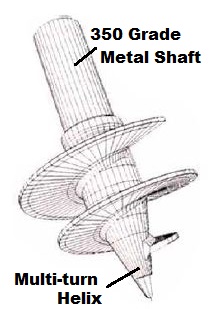

The components of a screw pile are the steel “Helix” (screw part) with a high strength steel “shaft” welded onto the Helix.

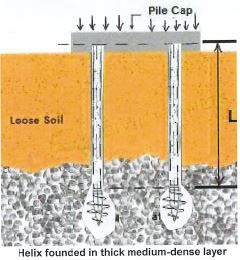

The metal Helix is the item that carries the pile load in ground when it is founded correctly at a depth, within a suitable medium-dense thick geotechnical layer in ground. The free end of the steel shaft is connected into the structure’s foundation elements to transfer the building loads down to the Helix.

What are the advantages when considering Screw Piles?

• In most instances when compared to concrete bored piers and CFA piling processes and construction time, steel screw piling is the more cost effective solution.

• Quick Installation– saving construction time, enabling the building to get out of the ground quicker,

eg ; screw piles for a standard residential house can be done within a day; a four to five storey

apartment block building could be done within 10 days.

• Unlike concrete bored piers, the steel screw piling installation process does not produce spoil that

requires removal from site, again another time and cost saving advantage.

• Because there is minimal spoil and sub-ground disturbance, screw piling is an optimum solution when

dealing with in ground contamination issues for construction.

• Sites with water tables close to the surface do not affect the screw piling installation, nor its load

carrying capacity.

• Environmentally friendly where Screw Piling installation involves minimal vibration and noise, with less

construction plant time onsite.

What are typical load capacities, lengths in ground, type of connection?

Typical SWL Load Capacity : The Helcon Screw Piling system can cater for SWL capacities from as little as 50kN up to 1,500kN per pile, ie, from 5 Ton up to 150 Ton capacity per pile.

Typical Pile Lengths : Screw Piles do not have to be founded onto rock to work. Rather, the technology involves being able to found the Screw Pile Helix within a suitable thick medium-dense geotechnical layer in ground. By screwing the Helix into the ground under an appropriate magnitude of torque, within that founding layer , the Helix develops a bulb of pressure resistance around it which resists the downward loading on the screw pile. So, the length of the Screw Pile is determined from the depth to the target layer in ground, or onto rock. In practice Screw Pile lengths in ground can be as little as 1 m , and as long as 18m in ground, even longer, but most common depths range between 3 ~9m in ground.

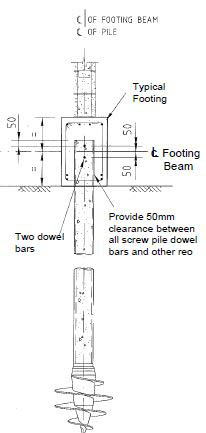

Typical Screw Pile Connection : Generally the free end of the Screw Pile will project into, and be incorporated into the foundation element like a footing , pile cap , drop panel / slab. Connection is normally achieved within the foundation element by using one to a number of horizontal dowel bars passed through the free end of the screw pile, or alternatively a number of vertical “L” cog bars that are slotted into the screw pile shaft and secured in place with concrete core filling of the pile shaft.

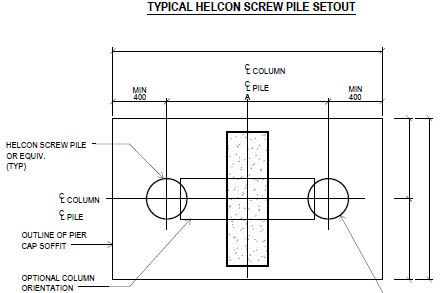

Typical Geometry : As a general rule of thumb the minimum centre to centre spacing between Screw Piles is three x the multi-turn Helix diameter. Minimum edge clearances from the centre of the screw pile shaft to outer footing face is 200~400mm.

NB: Helcon does not undertake the design of the connection detail nor pile caps etc. These foundation elements remains the Project Structural Engineer’s responsibility as they have the full understanding of the structure’s load paths and different types of load actions to be handled by the foundation elements within their footing design.

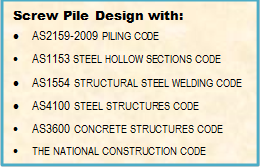

What does the Screw Pile design involve?

Basically, we use the Project Structural Engineer’s screw pile footing layout together with their screw pile design Load Schedules to determine the size of Helix and number of screw piles required. We use the Geotechnical Report to determine the target founding layer in ground which determines the length of pile, and may also influence the final size of Helix selected. We use the Architectural sections to understand the RL’s involved with the structure, when comparing to the Geotechnical Borehole RL’s to help fine tune the design length of screw pile. The selected screw pile shaft also has to have suitable torsional strength to resist twisting failure during the installation process, and suitable effective length strength when carrying the compression loads to avoid buckling failure

When determining the length of the screw pile, Helcon will also consider the depth of footing and whether the screw pile will be installed at natural ground level, or from the excavated foundation level.

The screw pile connection into the structure’s foundation element (ie; pile cap/footing/slab) is designed by the Project Structural Engineer. Generally the connection involves the head of the screw pile projecting into the concrete pile cap/ footing/slab with either horizontal reinforcement dowel bars installed through the head of the screw pile shaft, or L-cog bars installed inside the screw pile shaft with the shaft core filled with concrete.

How are Screw Piles installed?

Installation involves an excavator fitted with a hydraulic drive motor, attached to its dipper arm, that uses the machine’s hydraulics to power the drive motor to screw the screw pile into the ground. The process is much like using a hand drill as a screw gun to drive a screw into a piece of timber.

The length of the screw pile is limited by the clearance height from ground level up to the bottom connection end of the drive motor. In general, a 5 Ton excavator can install a 4m long screw pile, and a 14T~30T excavator can install a 6m long screw pile.

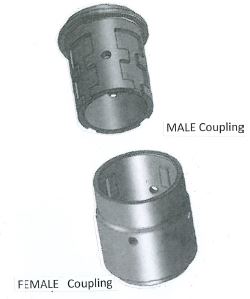

To get longer lengths in ground, screw pile extensions are used. Rather than increase construction time and site costs by welding extensions onsite, Helcon use a Male – Female coupling assembly that is welded onto the screw pile and extension during initial workshop fabrication. During installation onsite the Male coupling from the extension inserts into the female coupling on the pile and mechanically locks to enable the extension to continue screwing the original screw pile deeper in ground to toward the target stratum layer. This Male-Female assembly saves considerable installation time and removes site costs for a site welder, and, has a better quality control being done in the controlled environment of the fabrication shop versus by hand in the field.

What does construction involve?

Screw Pile Fabrication lead time

• When planning your construction program allow at least 10 work days for the screw pile fabrication schedules.

Depending upon current orders, this lead time can be shorter.

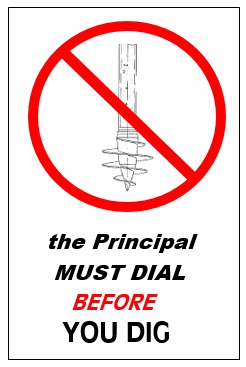

Site Preparation by Principal

• Determination and location of in ground / overhead services.

(Including exposing, moving, protecting, or terminating prior to screw pile installation).

• Bulk excavation to final RL – depending on the screw pile layout, installation can be done at

ground level with footings dug out afterwards, or direct into the excavated footings.

• Screw pile survey set-out of install marks.

Helcon Logistics

• Screw Pile packs are delivered to site by 10-Ton rigid tray HIAB truck.

• The excavator pile rig is floated to site on a low loader semi or flatbed truck.

• Screw Pile stock horizontal and vertical movement onsite is by the excavator.

Helcon Site Crew

• The site crew involves an excavator operator who is our site foreperson, and a spotter/ground

worker who works with the operator.

Helcon Installation and ITP’s

• Our Screw Pile Designer prepares ITP’s for the site crew to use to control the installation in accordance with his screw pile design. These control documents are the “Marked Up Plan” of the screw pile set-out and the “Installers Log”:

– the Helcon designer hand marks up the Project Engineer’s drawing of the screw pile

layout, where he numbers each pile on the plan uniquely ;ie; 1, 2, 3,…..etc.; and he also

uses a highlighter texter to colour code each pile on this Marked Up Plan according to

the designated screw pile type to be used.

– the Helcon designer then prepares the operator’s Install Logs where the same unique

numbering is used in the logs where pile No. 1 on the Marked Up drawing layout

corresponds to screw pile No. 1 in the Installers Logs, Pile No.2 and so forth.

– the Install Logs tabulate the Pile Type, Pile Length, Extension Length (if used),

Minimum Design Torque. During installation the Helcon Operator will write the Actual

Screw Pile length installed in ground , the Actual Install Torque achieved, and the date

of install.

• During installation the site crew have direct contact with the Helcon Designer to report and seek direction on any

site anomalies they may encounter during installation.

• Once screw pile installation has been completed the screw piles are cut to the Site Principal’s nominated finish height. Screw Pile cutting and blowing of holes for dowel bars is done by oxy/acetylene. The Helcon Quotation allows piles to be cut once to height and will specify how many site visits are allowed to complete this task. Cutting can be done during installation if the footings are at their final RL, otherwise cutting is done in a return visit once the footings have been dug to their final RL.

• After installation works are complete the Marked Up Plan and Installation Logs are reviewed by Helcon before sending to our nominated chartered Professional Engineer for independent review/sign off and Certification.

WHSE Documentation

• The Helcon office prepares and submits site specific High Risk SWMS to the site Principal.

• The SWMS submission includes Safe Work Instructions for the various Screw Piling work

activities undertaken on site, and also includes a Hazardous Substance Register with

associated Safety Data Sheets.

• Plant Records are also submitted which show the make, model and serial No. of the excavator

allocated to the works, together with its Plant Risk Assessment, Service Register, and

underlying plant Service Reports.

• All site crews have White Cards; and Operators hold relevant LE Tickets or VOC issued by

approved RTO.

Why do I need a Screw Pile Certificate?

Helcon use an independent chartered Professional Engineer to review and sign off our design and installation. These Engineers have structural and geotechnical background, understand the Screw Piling technology, and are familiar with the Helcon product. They will issue a Screw Pile Certificate for your submission to the Private/Council Certifier, or for the Project Engineer responsible for the works.

The full Helcon process from quotation to certification - No fuss - Job Done.

Get Building.

To obtain a quotation fill out the form

attaching the required documents.

NOTE: If your current Tender Document is based upon a bored pier design, please contact the Project Engineer to see if they will accept an alternate design involving a Screw Piling option. If yes, then also request the Project Engineer to provide their SWL’s that the screw piles are to carry.