Your Screw Piling SolutionStarts with Helcon

From experienced design to quick installation

and certification, no fuss, job done.

What are Screw Piles?

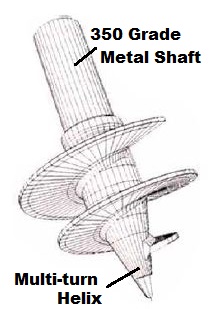

The components of a screw pile are the steel “Helix” (screw part) with a high-strength steel “shaft” welded onto the Helix.

The steel Helix is the item that carries the pile load in the ground when it is founded correctly at a depth, within a thick medium-dense stratum layer in the ground. The free end of the steel shaft is connected to the structure’s foundation elements to transfer the building loads down to the Helix.

Original technology involved a split flat plate Helix. However, like most technology, innovation and further developments within this technology have led to the development of the Multi-turn Helix, which Helcon use.

Helcon favours the Multi-turn Helix as the screw pile shaft is butt welded to the end of the Helix which gives a more stable assembly for load transfer, as against the split plate arrangement where that Helix is connected by welding circumferentially around the pile shaft and therefore the load transfer to Helix plate is against this weld, whereas with the Multi-turn assembly the load is direct into the Multi-turn Helix. The load carrying capacity of a Multi-turn Helix is greater than that of a split plate Helix when compared to their similar diameters.

Typical Safe Working Load (SWL) capacities for individual Screw Piles range from 50 kN to 1,500 kN ; (or 5 Ton to 150 Ton).

What are the advantages when considering using Screw Piles?

• In most instances when compared to concrete bored piers and CFA piling processes and construction time, steel screw piling is the more cost-effective solution.

• Quick Installation– saving construction time, enabling the building to get out of the ground quicker,

eg; screw piles for a standard residential house can be done within a day; a four to five storey

apartment block building could be done within 10 days.

• Unlike concrete bored piers, the steel screw piling installation process does not produce spoil that

requires removal from site, again another time and cost saving advantage.

• Because there is minimal spoil and sub-ground disturbance, screw piling is an optimum solution when

dealing with in ground contamination issues for construction.

• Sites with water tables close to the surface do not affect the screw piling installation, nor its load

carrying capacity.

• Environmentally friendly where Screw Piling installation involves minimal vibration and noise, with less

construction plant time onsite.

How do I get a Design & Construct Screw Piling quotation?

To obtain a quotation just send Helcon the following documents:

– Geotechnical Report

– Structural Plans

– Architectural Plans

To obtain a quotation fill out the form

attaching the required documents.

NOTE: If your current Tender Document is based upon a bored pier design, please contact the Project Engineer to see if they will accept an alternate design involving a Screw Piling option. If yes, then also request the Project Engineer to provide their SWL’s that the screw piles are to carry.